Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

$ 15.00 · 4.9 (563) · In stock

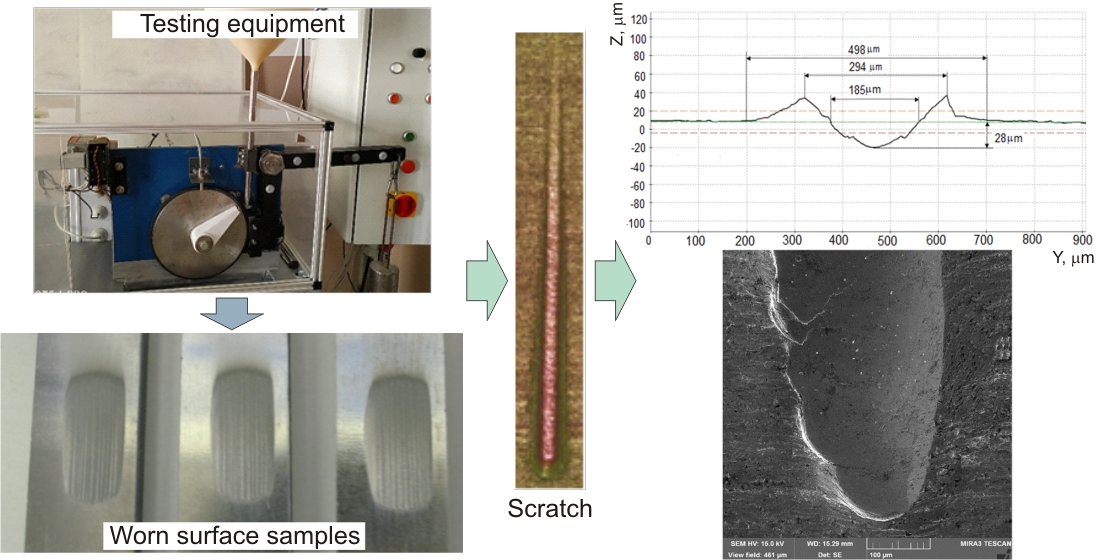

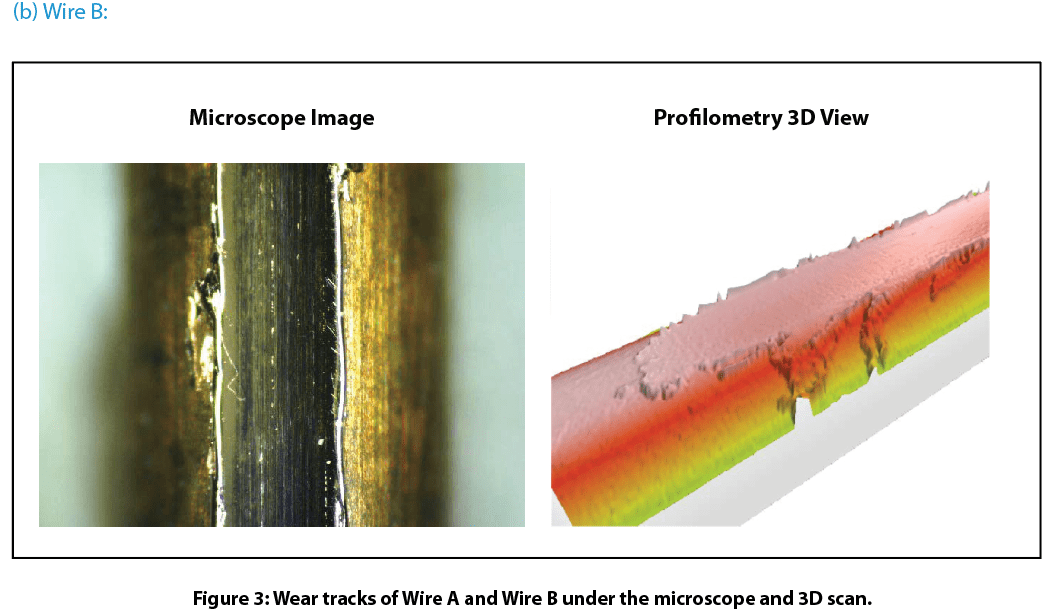

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

Corrosion behavior and wear resistance of Zr-2.5Nb alloy after thermal oxy-nitriding treatment - ScienceDirect

Guide to Jewelry Finishing Sandpapers - Halstead

Lubricants, Free Full-Text

What is Pitting Corrosion? How to detect and treat pitting corrosion?

TowSmart 80 in. Under Magnetic Towing Trailer Light Kit 1402 - The Home Depot

Black Oxide Coating Finishing Ultimate Guide In CNC Machining

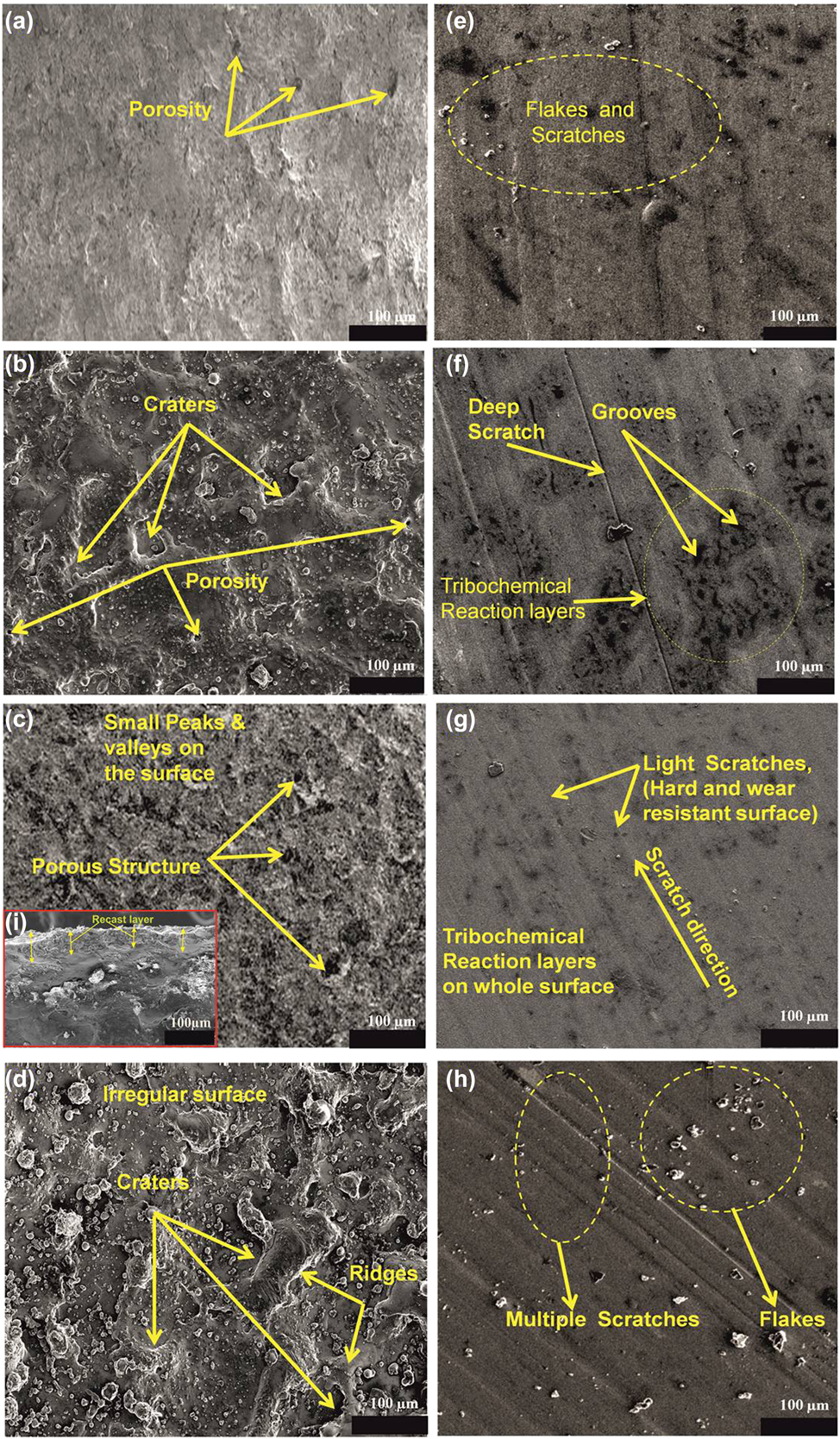

Potential of electrical discharge treatment to enhance the in vitro cytocompatibility and tribological performance of Co–Cr implant, Journal of Materials Research

They are solid brass, which means they are soft enough to cleaning or deburring with no scrach. Versatile kit & Commonly used for: Commonly used for

Brass Wire Wheel Brush Kit for Drill,Crimped Cup Brush with 1/4-Inch Shank,0.13mm True Brass Wire,Soft Enough to Cleaning or Deburring with Less

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

The UMT-2 tribometer for the wear test, scratch test and small punch

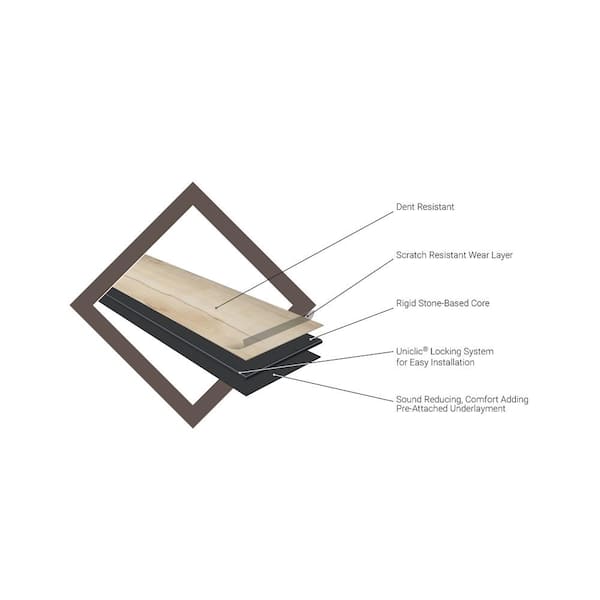

A&A Surfaces Arbor Oak 12 MIL x 7.1 in. W x 48 in. L Click Lock Waterproof Luxury Vinyl Plank Flooring (28.5 sq. ft./case) HD-LVR6520-0131 - The Home Depot

Sensors, Free Full-Text

Understanding the Different Types of Abrasion Testing - The TABER Test

The Role of Submerged Arc Welding in Heavy Fabrication - Red-D-Arc Red-D-Arc

ProtectaClear 4 Oz. Clear, Protective Coating for High-Touch Metal