Increasing Strength and Reliability of Interference Fits

$ 10.00 · 4.8 (443) · In stock

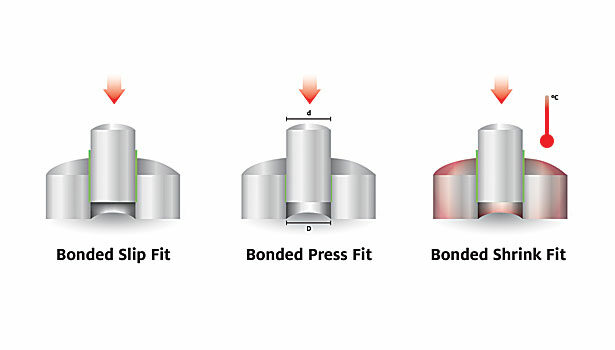

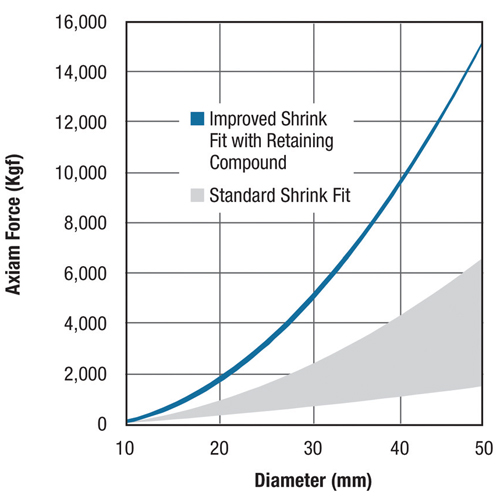

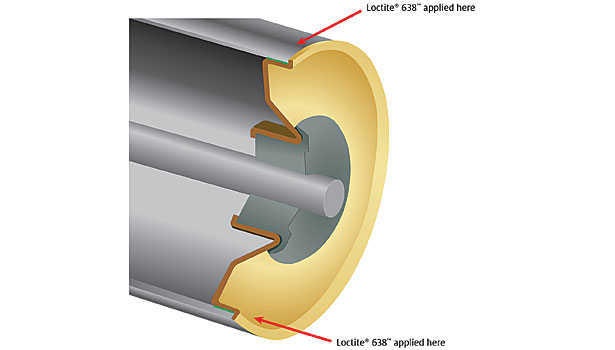

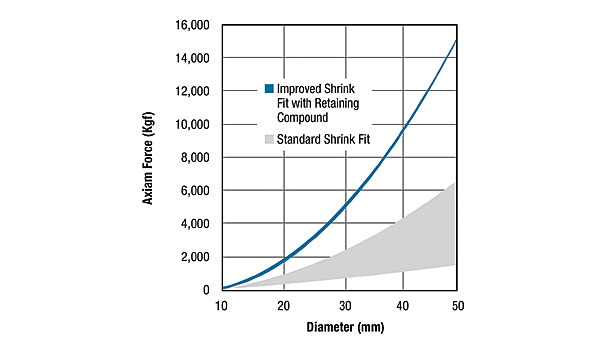

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts. In an interference fit, the inner part—such as a shaft, bearing or bushing—is machined to be bigger than the mating hole of the outer part—such as a gear or housing. The larger part is then forced into the smaller part. Both parts deform slightly to fit together and extremely high friction results between them. The friction is so great that even large amounts of torque cannot separate . . .

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts.

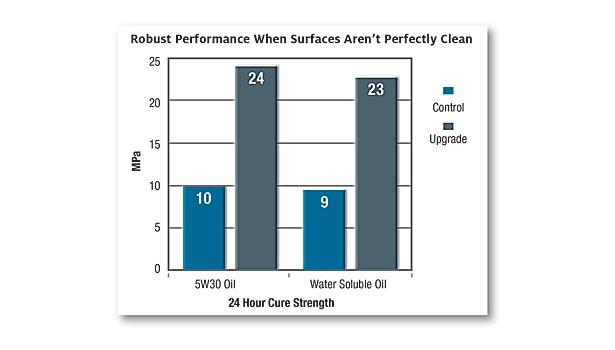

Increasing strength and reliability of interference fits: Retaining compounds enable engineers to design robust, lightweight joints at less cost than traditional interference fits

Increasing Strength and Reliability of Interference Fits, press fit

Assembly Presses, Assembly

Types of Fits: How to Choose a Fit for Engineering Application - WayKen, press fit

Increasing Strength and Reliability of Interference Fits, 2013-10-01, Assembly Magazine

Increasing Strength and Reliability of Interference Fits, 2013-10-01, Assembly Magazine

Increasing Strength and Reliability of Interference Fits, 2013-10-01, Assembly Magazine

Shaft/Hole Tolerances For Clearance & Interference Fits, press fit

Shaft/Hole Tolerances For Clearance & Interference Fits, press fit

Increasing Strength and Reliability of Interference Fits, press fit

Adhesives Assembly, Assembly

Increasing Strength and Reliability of Interference Fits, 2013-10-01, Assembly Magazine, press fit

Shaft/Hole Tolerances For Clearance & Interference Fits, press fit