NASA Uses Twin Processes to Develop New Tank Dome Technology

$ 16.50 · 4.5 (730) · In stock

(PhysOrg.com) -- NASA has partnered with Lockheed Martin Space Systems in Denver, Colo., and MT Aerospace in Augsburg, Germany, to successfully manufacture the first full-scale friction stir welded and spun formed tank dome designed for use in large liquid propellant tanks.

(PhysOrg.com) -- NASA has partnered with Lockheed Martin Space Systems in Denver, Colo., and MT Aerospace in Augsburg, Germany, to successfully manufacture the first full-scale friction stir welded and spun formed tank dome designed for use in large liquid propellant tanks.

La mission Insight - SEIS / Mars InSight

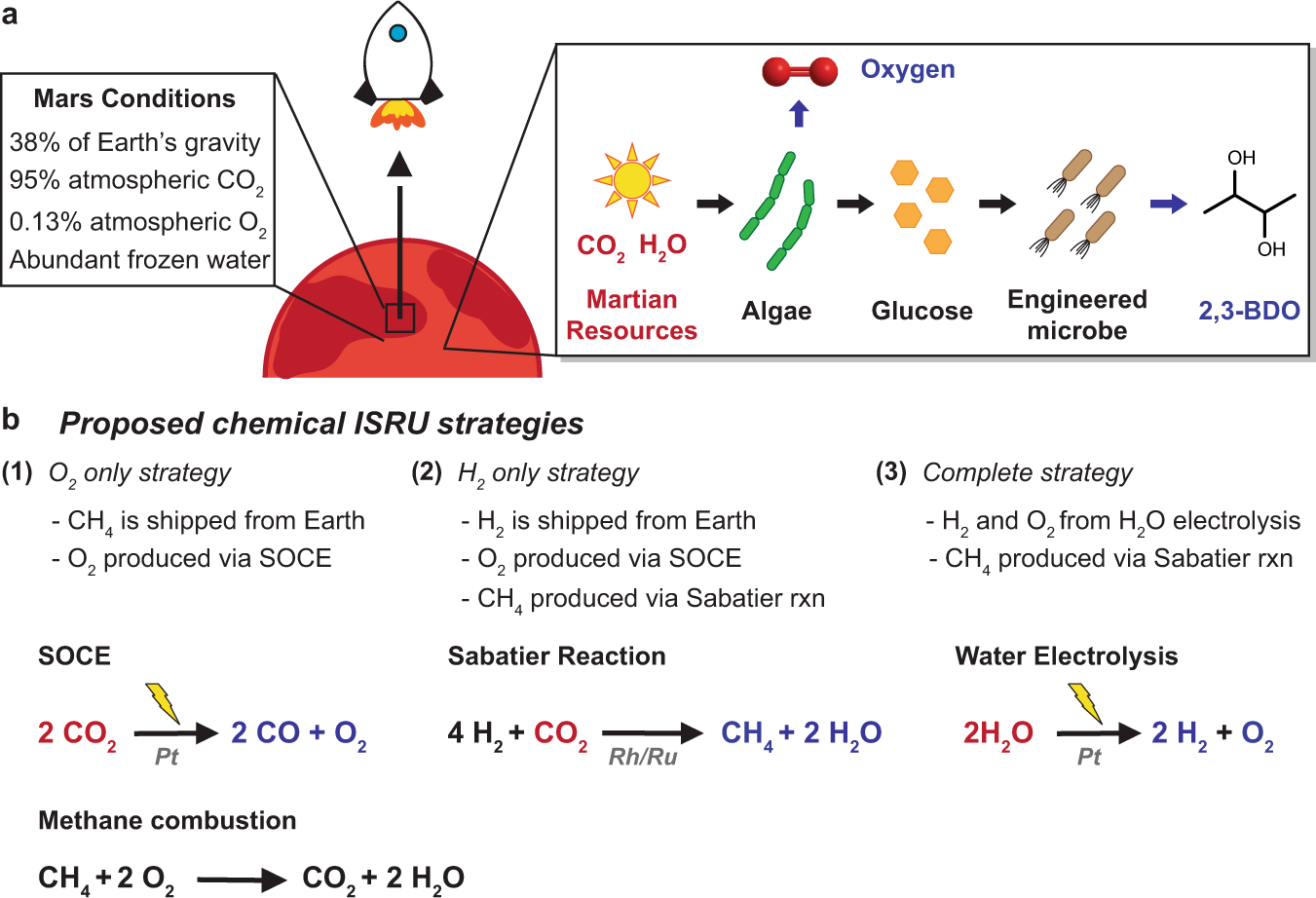

Designing the bioproduction of Martian rocket propellant via a

RAMFIRE Project Develops, Tests 3D-Printed Aluminum Rocket Engine

Orion crew module Archives - Universe Today

Michoud Assembly Facility Archives - Universe Today

NASA/Boeing composite launch vehicle fuel tank scores firsts

New welding discovery could radically improve manufacturing practices

NASA's Twin Processes for New Tank Dome Technology - Aerospace

NY's fossil fuel use soared after Indian Point nuclear plant closure

Schematic representation of laser powder bed fusion (credits NASA

News How a trash compactor will help get astronauts to Mars