Binders Used for the Manufacturing of Composite Materials

$ 17.50 · 4.6 (608) · In stock

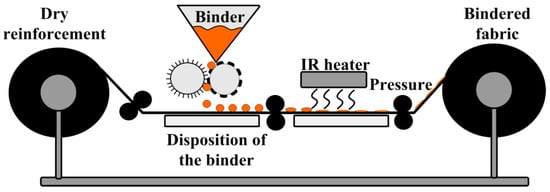

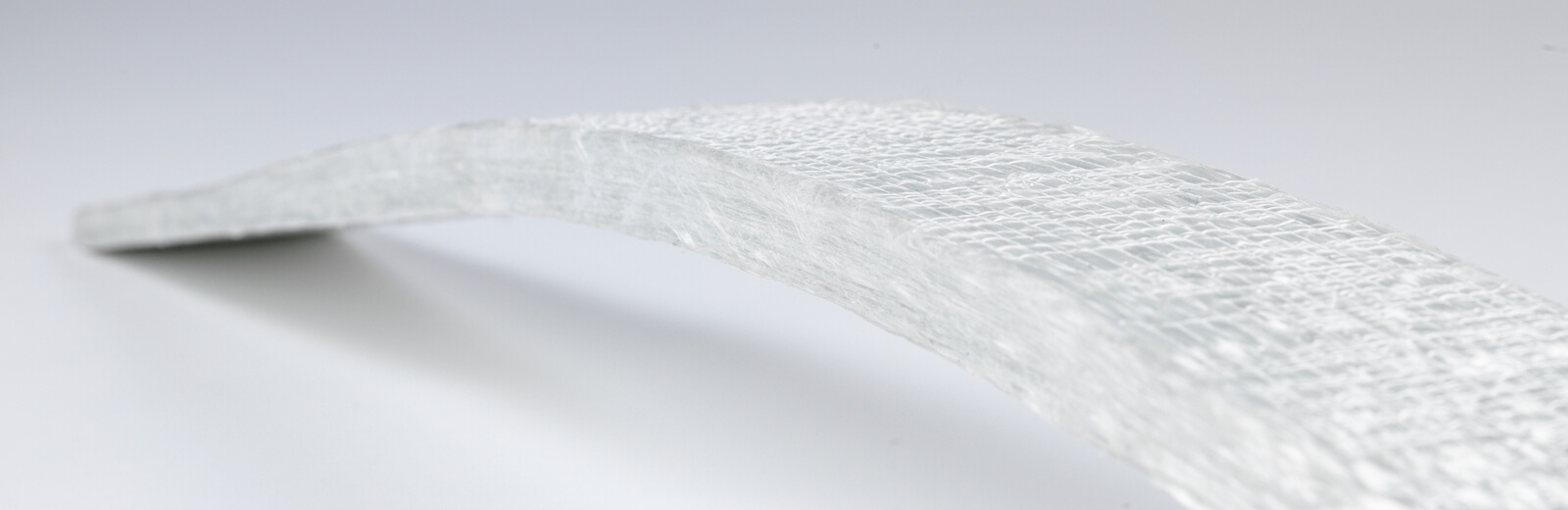

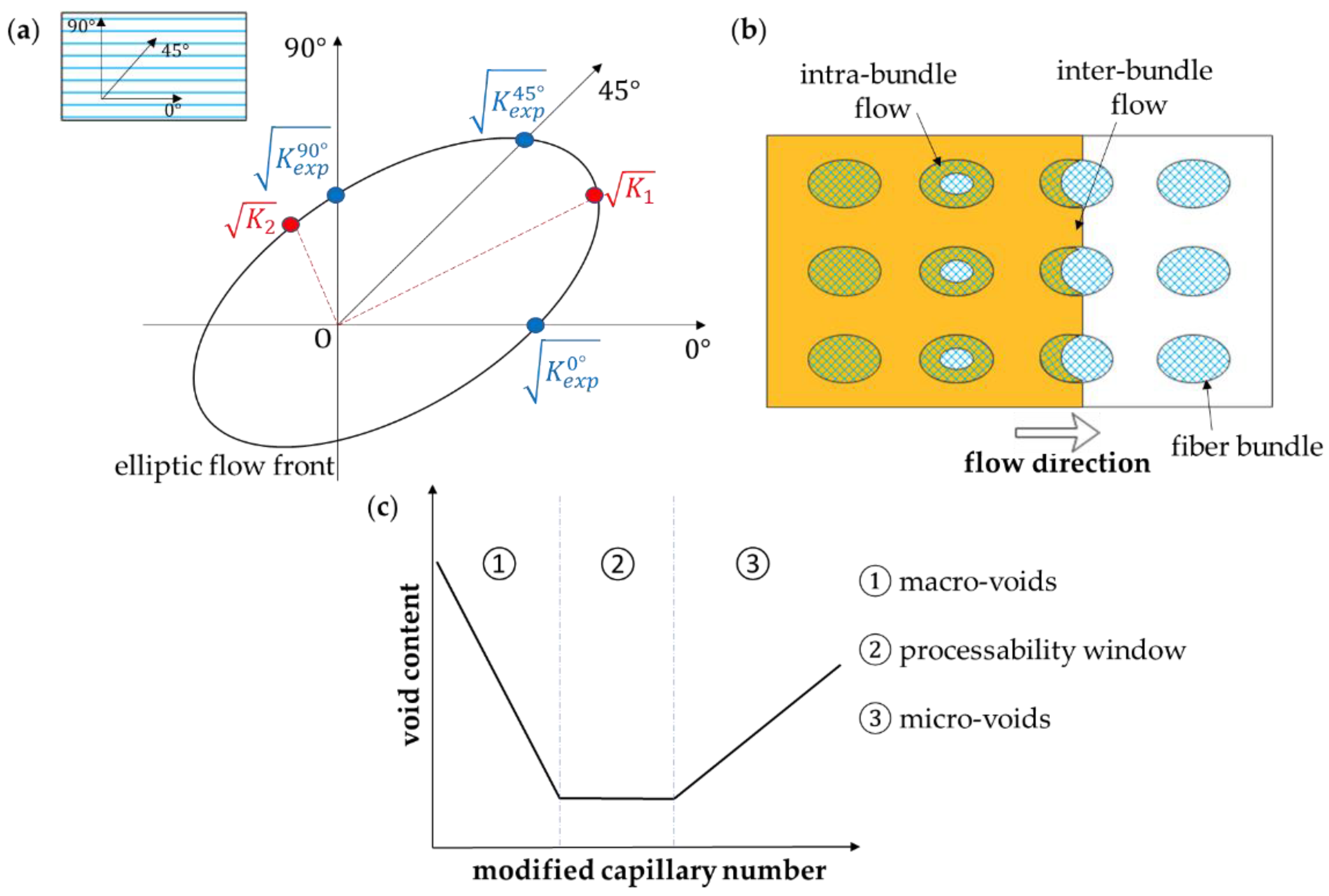

Binders, or tackifiers, have become widespread in the production of new composite materials by liquid composite molding (LCM) techniques due to their ability to stabilize preforms during laying-up and impregnation, as well as to improve fracture toughness of the obtained composites, which is very important in aviation, automotive, ship manufacturing, etc. Furthermore, they can be used in modern methods of automatic laying of dry fibers into preforms, which significantly reduces the labor cost of the manufacturing process.

Binder Jetting 3D Printing – The Ultimate Guide

PDF) EXTRACTION AND PHYTOCHEMICAL SCREENING OF TANINS FROM THE

The Tg of the matrix resin decreases with increasing polyester loading

Preforming Process Huntsman Transportation

B2B Portal: The Environmentally-Friendly

Polymers, Free Full-Text

Curing of an epoxy adhesive with fixed-frequency microwaves in the presence of a microwave absorber (activated carbon) and with the variable frequency microwave method,Journal of Applied Polymer Science - X-MOL

Why do we use aluminum dihydrogen phosphate as binder when

978-1-60595-681-7, ©2023, 410 pages, 6x9, Hardcover

Tooling for Composite Parts & Assemblies