Lubricants, Free Full-Text

$ 15.00 · 4.8 (449) · In stock

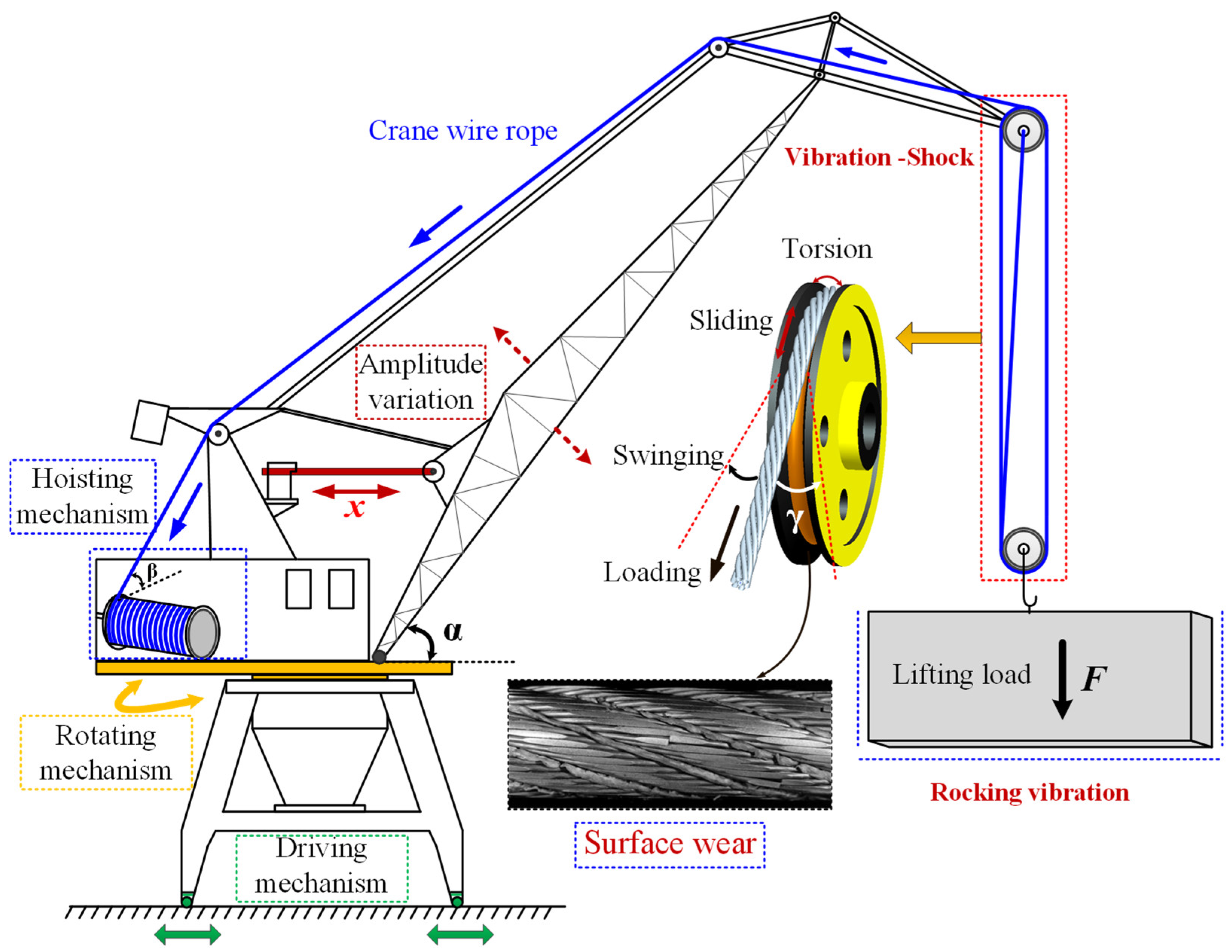

Surface wear caused by contact between crane wire rope and a pulley seriously affects the mechanical properties of the wire rope. In this study, the tribological behavior of wire rope was investigated using a homemade rope–pulley sliding friction test rig. Then, the influence of different surface wear on the bending fatigue life of the rope samples was analyzed. The results show that the friction coefficient (COF) decreases with the increasing sliding distance. It reaches a minimum of approximately 0.52 when the contact load is 700 N. The surface temperature of the wire rope rises rapidly and then gradually stabilizes. The maximum temperature rise fluctuates in the range of 50 °C to 60 °C with increasing contact load. The wear scar of the wire rope is irregular, and the maximum wear width increases from approximately 1.94 mm to 2.45 mm with the contact load. Additionally, increased contact load leads to smoother wear surface of wire rope, and the wear mechanisms are mainly abrasive wear and adhesive wear. Additionally, surface wear leads to a decrease in the bending fatigue life of wire ropes, and degradation of anti-bending fatigue is more serious under a larger sliding contact load.

Lubrita introduced special full synthetic high grade zinc-free hydraulic oils

Wasserfreie Schmierstoffe von LBI oil free

Loosen All Multi-Purpose Lubricant - TSE BIG MAX

Lubricants, Free Full-Text

20+ Lubricants Templates Free Graphic Design Templates PSD Download - Pikbest

Sliquid Swirl Lubricant Sample Pack Strawberry Pomegranate .17oz - Karnation Intimate Apparel Inc.

Lubricant Vectors & Illustrations for Free Download

HCR 1+2, hill climb racing 2 unblocked

Schematic illustration of gear lubrication and cooling by means of

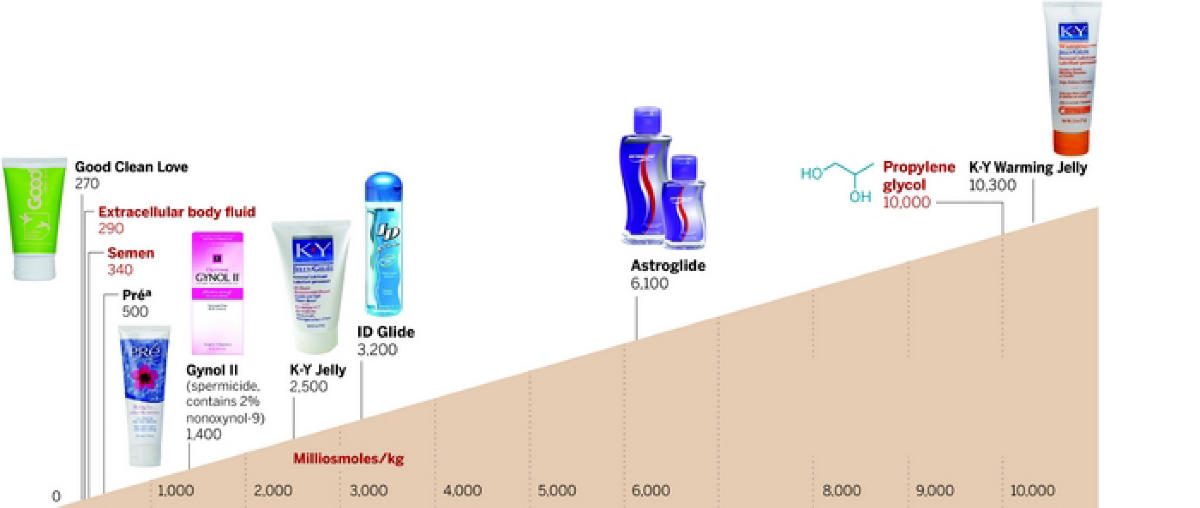

What You Should Know About Lubricant Toxicity, toxicity

Lubricants, Free Full-Text

Lubricants, Free Full-Text

Base Oil Groups Explained

PETRONAS Lubricants International (PLI)